Camp Chef PG24XT Review – Precision Pellet Heat & Versatility

Camp Chef PG24XT: Why grill selection matters for backyard cooks

Choosing the right grill or smoker shapes cooking outcomes, workflow, and long-term satisfaction. For buyers focused on wood-fired flavor with automated convenience, a pellet grill like the Camp Chef PG24XT positions itself between traditional charcoal and modern gas systems. Selection should match intended cooking styles—low-and-slow smoking, mid-range roasting, or higher-temperature grilling and searing—and account for fuel logistics, available space, and temperature precision needs. Key considerations include the fuel system (pellets and auger feed), temperature range and controller type, cooking surface and capacity, and maintenance features like ash management. Durability of materials and parts availability also factor into lifecycle cost and resale value. The PG24XT targets backyard cooks who want a single unit capable of multiple techniques, offering a digital control scheme and a stainless probe while relying on corded electric power for electronics. Evaluating the PG24XT requires weighing automated temperature control and pellet-fueled smoke profile against factors like sear performance, pellet dependence, and routine cleaning requirements.

Quick Overview

| Feature | Details |

|---|---|

| Grill type | Wood-pellet pellet grill and smoker |

| Fuel type | Wood pellets (automatic auger feed) |

| Total cooking area | 570 square inches (primary plus secondary racks) |

| Temperature range | 160 to 500 F |

| Materials & construction | Stainless steel firebox; powder-coated exterior components; steel grates (manufacturer specs) |

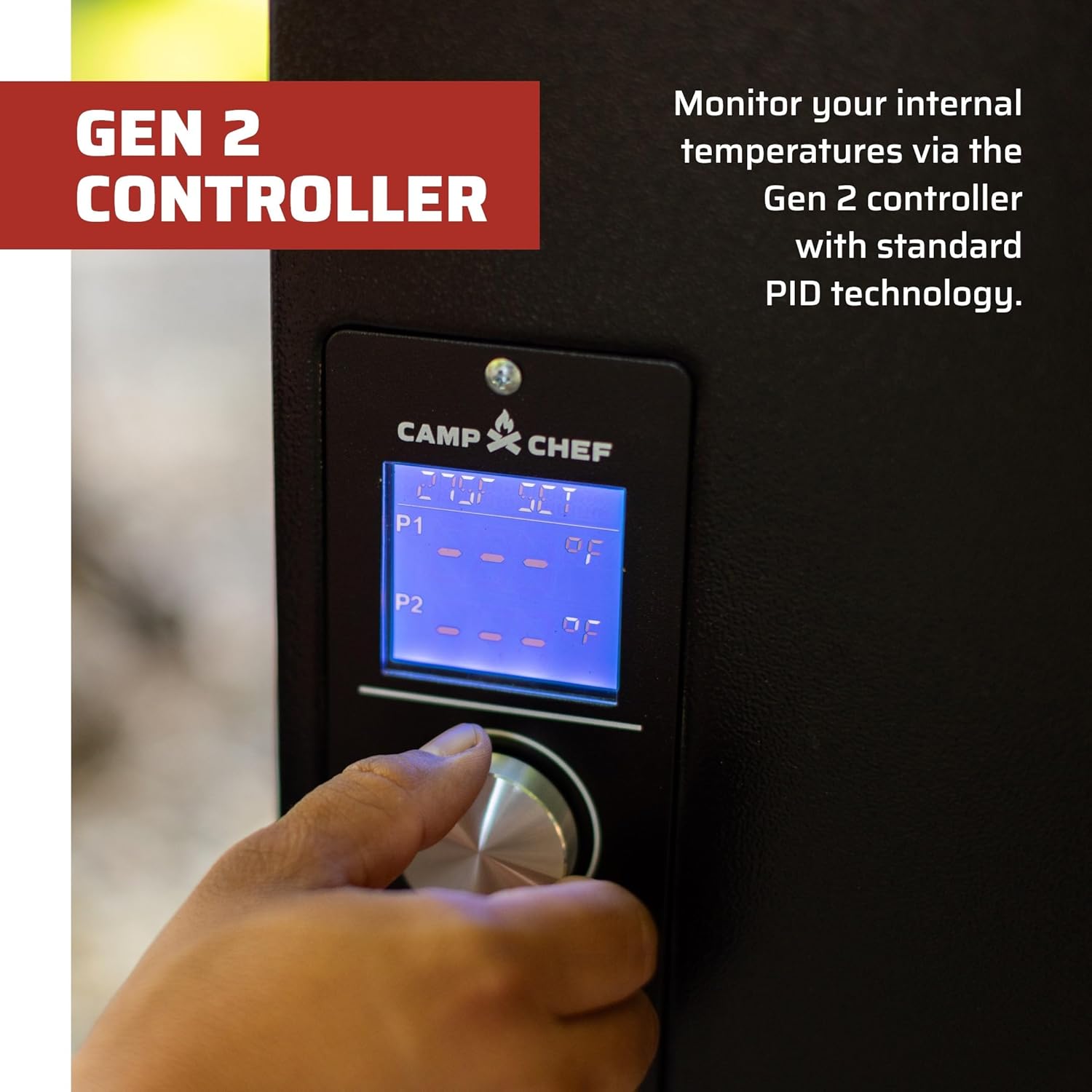

| Control system | Digital temperature controller with automatic auger and stainless temp probe |

| Best suited cooking styles | Smoking, indirect baking/roasting, grilling, braising, low-and-slow barbecuing |

| Intended use cases | Backyard entertaining, multi-course weekend cooks, smoking larger cuts |

| Warranty | Manufacturer limited warranty (consult Camp Chef for terms) |

The table condenses core specifications into buyer-focused facts. The PG24XT’s pellet fuel system and digital controller enable set-and-hold temperature workflows suitable for smoking and roast-style cooking, while the 570 square inches of cooking area accommodates family meals and small gatherings. The stainless firebox and manufacturer-provided probe support durability and temperature monitoring but require routine cleaning and pellet supply management to maintain performance.

Cooking versatility: grilling, smoking, roasting, and baking suitability

The Camp Chef PG24XT is positioned as a multi-function pellet grill aimed at cooks seeking wood-fired flavor with automated temperature control. The 160–500 F temperature span allows both low-and-slow smoking and higher-temperature grilling, though pellet grills characteristically deliver more even indirect heat than direct-sear intensity. The digital control and meat probe support multi-stage cooks and roast-style applications such as baking and braising. Versatility depends on technique adjustments—using direct-heat accessories or cast-iron griddles can expand sear performance, while the rack layout supports smoking racks and rotisserie-style items if aftermarket components are added. Buyers should consider how frequently each cooking style will be used and whether supplemental tools will be needed to achieve high-heat searing comparable to gas or charcoal sear stations.

Low-and-slow smoking performance and flavor profile

Pellet grills like the PG24XT use compressed hardwood pellets and a controllable auger feed to generate smoke and maintain stable low temperatures. At 160–225 F, the unit supports classic smoke chemistry—wood combustion produces phenols and carbonyls that adhere to meat surfaces, creating recognizable smoke flavor without excessive creosote when run at controlled temperatures. The digital control smooths temperature variance during long cooks, which helps maintain consistent smoke ring development and collagen breakdown in brisket or pork shoulder. Pellet selection (apple, hickory, mesquite) influences the dominant flavor notes, and pellet quality affects burn consistency and ash production.

High-heat grilling and searing capabilities

The PG24XT’s upper range to 500 F enables grilling tasks and faster cooks, but ceiling sear performance depends on grate-to-firebox geometry and heat delivery method. Pellet grills deliver excellent radiant and convective heat for indirect grilling; however, achieving a Maillard crust comparable to a charcoal chimney or dedicated gas sear burner may require a searing plate, cast-iron skillet, or a short, high-temperature preheat with direct-heat accessories. For cooks prioritizing frequent high-heat searing, pairing the pellet grill with a dedicated sear accessory or choosing a hybrid setup will influence satisfaction with results.

Baking, roasting, and indirect cooking adaptability

The PG24XT’s digital temperature control and even heat distribution are suited to oven-style cooking tasks such as baking pizzas, roasting whole poultry, and braising. The stable set-and-hold capability simplifies multi-hour roasts and delicate baking items that require precise temperatures. The stainless temp probe allows internal doneness checks without opening the lid frequently, which conserves heat and maintains consistent cooking environments. Accessories such as pizza stones or rib racks broaden indirect cooking options, enhancing the grill’s versatility for multi-course outdoor kitchens.

Fuel system, temperature control precision, and monitoring

Fuel type and control architecture define a pellet grill’s predictability and user experience. The PG24XT’s automatic auger feed and smart digital temperature control are designed to maintain target temperatures by metering pellets into the burn pot. This automated system reduces active adjustments compared to manual charcoal tending but introduces dependency on pellet supply, pellet quality, and the pellet sensor/auger mechanism. The specified range from 160 to 500 F covers most smoking and roasting tasks, while the included stainless temp probe provides internal meat temperature tracking. Buyers evaluating control precision should consider how the controller responds to ambient conditions and lid openings, and whether additional monitoring tools or aftermarket PID upgrades are desired for tighter tolerance cooks.

Pellet fuel characteristics and efficiency considerations

Wood pellets offer a convenient, consistent fuel with predictable BTU output per pound and low handling complexity compared with loose wood or charcoal. High-quality pellets reduce fines and dust that can clog the auger and create uneven feeding; moisture content affects combustion efficiency and smoke production. Pellet consumption increases with higher set temperatures and open-lid recovery cycles, so long cooks at mid-range temperatures tend to be fuel-efficient while rapid high-temperature searing consumes more pellets. Storage of pellets in a dry environment preserves burn consistency and minimizes maintenance related to pellet degradation.

Digital controller behavior and temperature stability

The PG24XT’s smart digital controller automates auger feeding to hold a set grill temperature, simplifying long cooks. Digital controllers vary in control algorithm aggressiveness: some use simple on/off cycling while others use PID-style adjustments for tighter stability. Manufacturer descriptions emphasize automatic feed and set-and-hold operation; aggregated user feedback for similar Camp Chef controllers highlights generally stable temperatures with occasional overshoot or delay during wide ambient swings or extended lid openings. For critical low-temperature smoke or precision baking, pairing the built-in controller with a secondary capo or external thermometer can provide redundancy and cross-checks for target-temperature adherence.

Temperature monitoring and probe utility

The included stainless temp probe provides real-time internal meat temperature readings without invasive thermocouples, supporting multi-stage cooks and reducing lid opens. Probe placement and wire routing impact accuracy—placing the probe into the thickest part of the meat while avoiding bone produces most reliable internal readings. External ambient thermometers or additional probes can help map temperature gradients across the cooking surface, revealing hot and cool zones and informing rack placement. Reliance on manufacturer-supplied probes reduces guesswork but users should factor in probe calibration and potential need for replacements over the grill’s service life.

Heat distribution, airflow management, and cooking capacity

Heat distribution and airflow characteristics determine how evenly food cooks and how smoke circulates. The PG24XT’s stainless firebox and internal heat path are engineered to move convective heat across the primary cooking area; however, pellet grills typically create a bias toward indirect heat rather than intense direct flame contact. The 570 square inches of usable rack space handles family-sized cooks and mixed loads, but rack configuration and distance from the burn pot influence temperature zones. Airflow management—driven by the exhaust vent, lid design, and body seams—affects smoke retention and combustion efficiency. Buyers should consider how the unit’s internal geometry and rack layout correspond to typical food volumes and whether supplemental accessories or rack reorganization is needed for even multi-rack smoking.

Internal heatflow and hot/cool zone mapping

Pellet grill heatflow tends to move from the burn pot upward and across under grates; the PG24XT’s stainless firebox helps reflect heat and resist corrosion from combustion byproducts. Common patterns show the area closest to the burn pot running hotter, producing a mild hot zone for finishing or reverse-sear techniques while opposite corners act as cooler zones ideal for low-and-slow items. Using multiple probes or placing identical items across the rack during a trial run reveals gradient patterns and informs best placement for large briskets versus thin ribs. Understanding the grill’s internal heat mapping reduces guesswork when expanding cooks to full rack loads.

Rack arrangement, total cooking area, and practical capacity

The listed 570 square inches includes primary cooking grates plus secondary racks, enabling simultaneous cooking of whole chickens, multiple racks of ribs, or several steaks. Real-world capacity depends on item size and spacing for adequate smoke penetration and airflow. For multi-rack smoking, steam and smoke circulation between racks matter; leaving slight spacing helps consistent smoke contact and heat transfer. For buyers frequently entertaining larger groups, modular rack accessories, rib racks, and vertical smoking inserts can multiply capacity without overcrowding the cooking chamber.

Airflow, smoke production, and exhaust design

Airflow is governed by intake through the burn pot, auger-driven combustion, and exhaust venting. Proper combustion requires sufficient oxygen; pellet grills like the PG24XT maintain combustion with a fan-assisted airflow pattern that also carries smoke flavors across food. The exhaust placement and lid sealing influence smoke dwell time—longer dwell time increases smoke deposition but can raise creosote risk at very low temperatures. Users should expect a relatively clean smoke profile when operating at recommended set points and with quality pellets, and should account for venting direction when locating the grill relative to structures.

Maintenance, durability, and ownership considerations

Long-term ownership and maintenance needs influence total cost of ownership and user satisfaction. The PG24XT’s patented Ash Cleanout system is designed to simplify ash removal from the burn pot, reducing the frequency of deep cleanings compared with manual ash scrapes. Stainless components in the firebox improve corrosion resistance, while powder-coated exterior parts balance cost and durability. Routine maintenance includes emptying pellet hopper, checking auger and motor function, cleaning grease traps and grates, and inspecting seals and probe connectors. Parts availability and manufacturer support for replacement components also factor into repairability and expected service life. Buyers should weigh these maintenance chores and expected longevity against how intensively the grill will be used and the availability of service in their region.

Ash management, grease control, and routine cleaning

The ash cleanout lever streamlines removal of combustion residue from the burn area, limiting the need to disassemble the pot after every cook. Regular cleaning intervals depend on pellet quality and cook frequency; high-usage scenarios require more frequent ash and grease management. Grease management systems—drip trays and channels—collect fats but need periodic emptying to prevent flare-ups and accumulation. Cleaning grates and interior surfaces with wire brushes and oven-safe degreasers maintains surface hygiene and helps prevent off-flavors, while attention to probe ports and wiring preserves electronic longevity.

Construction materials, corrosion resistance, and expected lifespan

Stainless steel in the firebox offers elevated resistance to rust compared with painted steel, particularly in areas exposed to combustion byproducts and moisture. Powder-coated exterior cabinetry balances weather resistance and cost, but prolonged exposure to elements like salt air or heavy precipitation accelerates finish degradation if left uncovered. Electrical components, the auger motor, and fans represent wear items; expected lifespan depends on use patterns, maintenance, and storage conditions. With regular maintenance and protected storage, similar pellet grills often provide several years of reliable use; component replacement cycles for probes and motors are common and typically manageable with available replacement parts.

Parts, serviceability, and who should avoid a pellet grill

Availability of replacement parts—auger motors, probes, controllers, ignition modules—affects repair turnaround and long-term usability. Camp Chef’s broad product ecosystem generally supports parts availability through dealers and the manufacturer, but regional service varies. Pellet grills require electricity for controller and auger operation, so off-grid users should plan for power access or alternative systems. Those prioritizing pure high-heat searing, absolute off-grid portability, or minimal routine cleaning may prefer gas, charcoal, or infrared options instead of a pellet system. Buyers who do not want to manage pellet inventory, ash, or periodic electronic parts maintenance should consider alternative fuel types.

Pros & Cons

Pros

- Automated temperature control simplifies long cooks while producing consistent smoke flavor. The digital controller and automatic auger reduce manual feeding and active temperature tending, supporting set-and-hold cooking workflows.

- Wide temperature range covers smoking to higher-temperature grilling. The 160–500 F span accommodates low-and-slow barbecue as well as faster roasting and higher-heat grilling tasks.

- Patented ash cleanout reduces cleanup time. The lever-based ash removal system minimizes disassembly and lowers the barrier to regular maintenance.

- Included stainless temp probe enables internal meat monitoring. Built-in monitoring reduces the need to open the lid and helps maintain steady cooking environments.

- Substantial cooking area supports family and small-group cooks. The 570 square inches of rack surface allows multiple items or multi-rack smoking for typical backyard entertaining.

- Stainless firebox material improves corrosion resistance where combustion byproducts concentrate. The firewall and internal surfaces gain added durability compared with painted steel alone.

Cons

- Pellet dependence and electrical requirement limit off-grid use. The auger, controller, and fan require consistent electricity and a steady pellet supply, making remote or non-powered locations less suitable.

- Limited direct-sear intensity without accessories. Pellet grills often need cast-iron or sear accessories to match the extreme high-heat crust achievable on charcoal or gas sear burners.

- Routine maintenance of auger, probe, and ash systems required. While ash cleanout eases the task, periodic inspection and cleaning of moving parts and grease channels are necessary to prevent issues.

- Potential for temperature variance during large lid openings or extreme ambient conditions. Like most pellet units, recovery time and controller response can lead to temporary overshoot or undershoot during frequent lid access or sudden weather changes.

Final Verdict: Who This Grill or Smoker Is Best For (and Who Should Skip It)

The Camp Chef PG24XT suits backyard cooks seeking an automated, wood-pellet solution that blends smoking, roasting, and mid-range grilling capabilities with a relatively large cooking area. Its digital controller, stainless temp probe, and patented ash cleanout appeal to users who prioritize convenience and consistent temperature maintenance during multi-hour cooks. The grill is a fit for families, weekend barbecue hosts, and cooks who value wood-fired flavor without constant fuel tending. Durability is supported by a stainless firebox and widely available replacement parts, making it a practical long-term option for regular outdoor use.

Conversely, the PG24XT is less suitable for off-grid campers or cooks who require extreme direct-sear performance as a primary function. Those who prefer minimal routine maintenance or absolute portability may favor gas or charcoal alternatives. Buyers should weigh the convenience of automated pellet feeding and digital controls against the need to manage pellet storage, electricity for operation, and occasional electronic component servicing when deciding if the PG24XT aligns with their cooking priorities in 2026.

Frequently Asked Questions (FAQs)

How precise is the Camp Chef PG24XT temperature control for low-and-slow smoking?

The PG24XT’s digital controller automates auger feeding to maintain set temperatures, supporting consistent low-and-slow smoking within the specified 160–500 F range. Precision depends on ambient conditions, lid openings, and pellet quality; typical behavior is stable set-and-hold performance with occasional recovery time after lid access. For critical low-temperature cooks, supplementary monitoring with an external thermometer can provide redundancy and confirm internal stability.

Can the PG24XT achieve a true sear comparable to charcoal or gas sear burners?

The PG24XT reaches up to 500 F, which supports higher-temperature grilling but may not match the direct, radiant sear intensity of charcoal or dedicated gas sear burners. Achieving a pronounced Maillard crust often requires accessories such as a cast-iron griddle or a sear plate that concentrates heat. For frequent heavy searing, pairing the pellet grill with a hybrid or dedicated sear source may be preferable.

What maintenance is required to keep the PG24XT operating reliably?

Regular maintenance includes clearing ash from the burn pot via the Ash Cleanout lever, emptying and storing pellets dry, cleaning grates and grease channels, and inspecting the auger and fan for debris. Periodic checks of the temperature probe and electrical connectors extend component life. Adhering to manufacturer cleaning intervals and using quality pellets reduces wear and preserves performance.

How does pellet fuel choice affect flavor and performance on this grill?

Pellet species and pellet quality influence smoke flavor and burn consistency. Fruitwoods like apple or cherry provide milder, sweeter smoke; hickory and oak yield stronger, more robust profiles. High-quality, low-moisture pellets produce steadier combustion and less ash, improving auger reliability and heat consistency. Pellet selection should match desired flavor intensity and cooking duration.

Is the PG24XT suitable for off-grid or remote use?

The PG24XT requires corded electric power to operate the controller, auger, and fan, and relies on a continuous pellet supply. This dependency makes it less suitable for off-grid settings unless a reliable portable power source and pellet storage are available. For remote cooking without electricity, charcoal or gas systems are typically more practical.

What size of gatherings can this grill handle comfortably?

With 570 square inches of total cooking area across primary and secondary racks, the PG24XT can handle family meals and small-to-medium gatherings, accommodating multiple racks of ribs or several whole chickens. Practical capacity depends on item size and spacing for smoke circulation; adding rack accessories can increase usable capacity for larger events.

How resistant is the PG24XT to corrosion and outdoor exposure?

The PG24XT uses a stainless steel firebox, which increases resistance to corrosion in high-heat and combustion-exposed areas. Exterior components often use powder-coated finishes that resist weathering but benefit from covered storage. Long-term exposure to harsh environments accelerates wear on painted surfaces and electrical components, so sheltered storage and routine maintenance improve longevity.

Are replacement parts and service readily available for the PG24XT?

Camp Chef maintains parts availability for common service items such as probes, auger motors, and controllers through authorized dealers and the manufacturer. Regional availability and turnaround times vary, so prospective buyers should confirm local dealer support for replacement components and service options to minimize downtime.